Research Areas

• Surface plasmon resonance (SPR) biosensors

• Plasmonic assisted photocatalytic process

• Semiconductor gas sensor with plasmonic enhancement

• Lab-in-a-tube

• Lab-on-a-discRecent Research Projects

Nano-materials for Photonic and Sensor Applications

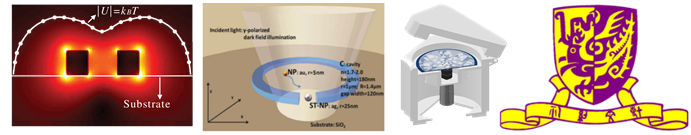

Surface plasmon resonance (SPR) spectronscopy, which detects the local change of refractive index in the proximity to the metal surface upon binding of target analytes to receptors, has evolved as a leading method for label-free detection. Currently, SPR sensors based on spectral, angular, and phase detections are available and each utilizes different plasmonic properties. For spectral and angular SPR, due to the change in the speed of surface plasmon polaritons (SPPs) in response to the change in refractive index, the shift of the resonant wavelength or angle can be used as a signature for detecting the presence of target analytes by scanning either the wavelength at a fixed angle or the angle at a fixed wavelength. On the other hand, phase based SPR relies on measuring the phase-difference between p- and s-outgoing fields to determine the refractive index change.

The working principle of SPR sensors is based on a unique and simple optical phenomenon. In this phenomenon, the collective coherent oscillations of free electrons in the conduction band of a metal is first excited by the interactive electromagnetic field at a metal/dielectric interface and these created charge density oscillations are called surface plasmon plaritons (SPPs).

There are two main types of SPR sensors: propagating SPR (PSPR) sensors and localized SPR (LSPR) sensors. PSPR is usually excited on continuous metal thin films through prism couplers or grating and PSP resonance can propagate along the metal/dielectric surface up to hundreds of micrometers, while LSPR is non-propagating surface plasmon excited on nanostructured metal surfaces and LSP resonance can be tuned by their size, shape and composition.

The main challenge for all electrical, mechanical and optical sensors is to detect low molecular weight (less than 400 Da) chemical and biological analytes under extremely dilute conditions. Surface plasmon resonance sensors are the most commonly used optical sensors due to their unique ability for real-time monitoring the molecular binding events. However, their sensitivities are insufficient to detect trace amounts of small molecular weight molecules such as cancer biomarkers, hormones, antibiotics, insecticides, and explosive materials which are respectively important for early-stage disease diagnosis, food quality control, environmental monitoring, and homeland security protection. With the rapid development of nanotechnology in the past few years, nanomaterials-enhanced surface plasmon resonance sensors have been developed and used as effective tools to sense hard-to-detect molecules within the concentration range between pmol and amol.

Noble metallic nanoparticles, especially gold nanoparticles (Au NPs), are commonly used nanomaterials for improving the sensing performance of PSPR sensors. These particles are also called plasmonic nanoparticles. They exhibit strong absorption in the visible and near-infrared wavelength regions. Consequently, a large electric field due to LSPR will be excited on the surface of the particles. It has been demonstrated that the SPR sensitivity is closely related to the excited electric field: the larger the electric field, the more sensitive of SPR sensors to the change of its surrounding medium.

Recently, functionalized magnetic nanoparticles (MNPs) such as Fe3O4 nanoparticles have been employed for signal amplification of PSPR sensors as well. Compared to plasmonic nanoparticles, the main advantages of using MNPs are that the production cost of the MNPs is lower and the step for initial receptor immobilization onto the SPR sensing film is not needed. Moreover, the MNPs can be attracted and manipulated by externally applied magnetic fields and form an ‘‘aggregate’’ layer with a strong refractive index contrast on the metallic sensing film that will lead to a notable SPR signal when sensing trace amounts of biological and chemical samples.

Recently, graphene-modified SPR sensing substrates have attracted much attention from the scientific community. It has been demonstrated that coating graphene layers on gold or silver thin films can induce larger SPR signal changes compared to those with bare metal thin films. This is mainly due to the charge transfer from graphene to the surface of metal thin film since their work function is different and this effect has led to a strong excited electric field enhancement at the sensing surface. Also, the highly selective adsorption of aromatic rings structure molecules (e.g., DNA and TNT) on the surface of graphene-modified SPR sensing substrate can be achieved through strong pi-stacking forces and this specific interaction will certainly open new avenues for ultra-sensitive detections of peptides, DNA, RNA and siRNA molecules.

Reference:

[1] Appl. Phys. Lett. 104, 171116 (2014)

[2] Chem. Soc. Rev., 2014, 43, 3426

Lab-on-a-disc

Lab-on-a-chip: A compact device of several square centimeters in size that brings several laboratory operations in one microarray for various biomedical applications, such as allergy testing.

Lab-on-a-disc: A microfluidic disc device with chambers, valves and channels that integrates laboratory operations in one platform using centrifugal, inertial and Coriolis forces generated by spinning for fluidic pumping, reagent mixing and metering for detecting disease markers.

Lab-on-a-disc (LOAD), or the centrifugal microfluidics platform, is a recent variant of LOAC. LOAD alleviates the need for active pumping by introducing centrifugal forces, capillary forces, Euler forces and Coriolis forces. The main benefit is that the forces are present everywhere on the disc for solution translocation, reagent mixing, target separation and for changing the direction of solution movement. This means that sample propulsion is always at the user’s disposal. Sample movement can be controlled by varying the spinning speed, spinning direction, valves or rotation- actuated barriers through different combinations of centrifugation force, capillary force, Euler force and Coriolis force.

Recently, we developed a LOAD system for allergy testing. Our disc design, with a diameter of 10 cm, contains four identical units for testing allergens. The channels (500-μm width and 250-μm depth) and chambers are made of polydimeth¬ylsiloxane, which is moulded with an SU-8 master made from photolithography; the siphon valve region is modified with titanium dioxide. The polydimethyl¬siloxane layer is attached to a flat polymethylmethac¬rylate (PMMA) disc. This disposable LOAD platform integrates reagent metering, mixing, reaction, analyte selection and signal generation and detection in an automated fashion.

Reference:

[3] Bioanalysis (2014) 6(14)