The Force is with Us

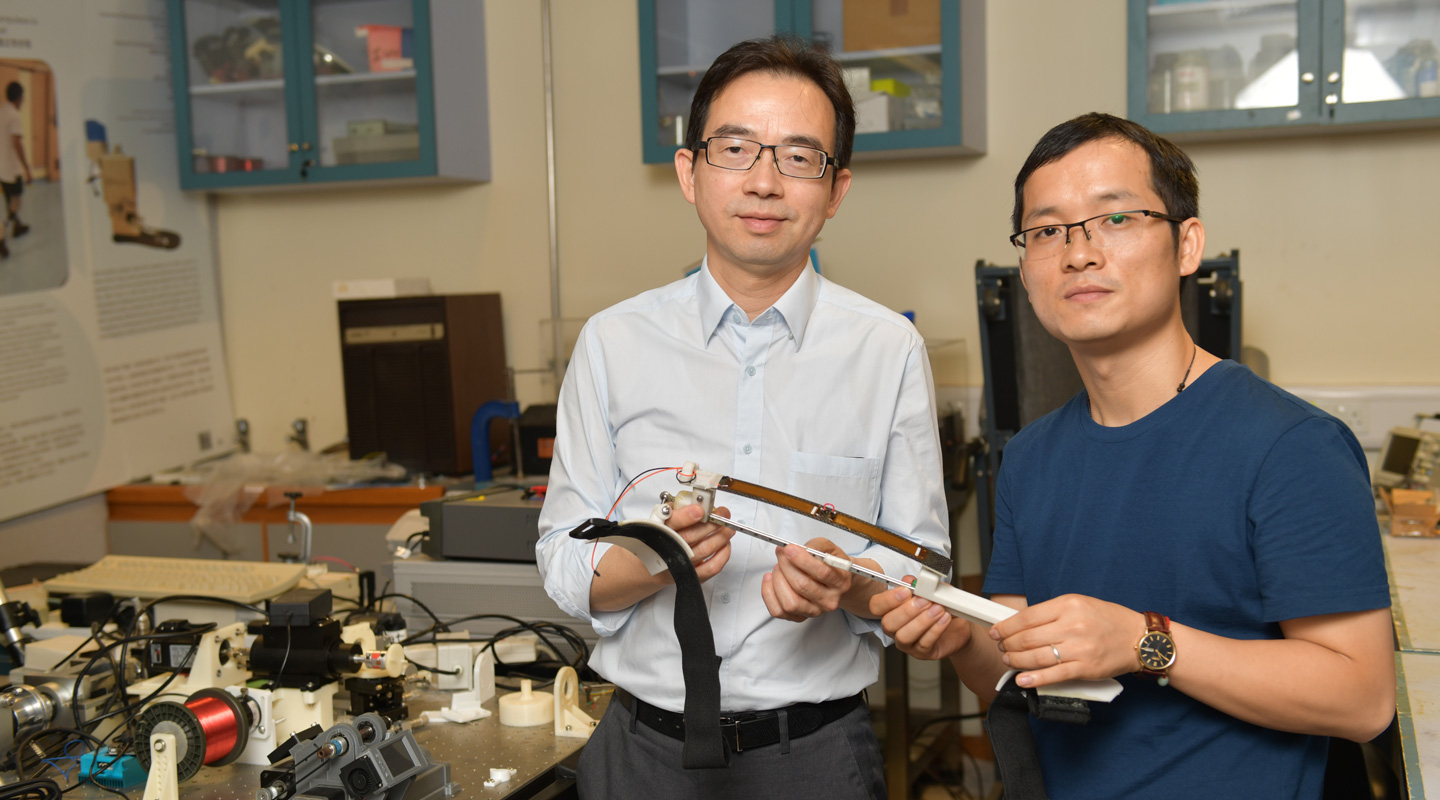

Liao Wei-hsin harvests energy from human motion

Anxiety over dying battery is a syndrome of our times. The fast dwindling life juice in that tiny battery icon on our smartphones fuels our fears, and it is only when we have managed to charge them our peace of mind is restored—actually, the pain caused by the low percentage feels so sharp and ubiquitous, few of us do not leave our phone plugged even when it hits the full charge. Thanks to the ingenious invention by mechanical engineers led by Prof. Liao Wei-hsin, chairman of Department of Mechanical and Automation Engineering, our paranoia about charging will soon come to an end. And the cure they discovered lies nowhere other than in our own knees; by donning the human knee energy harvester which flaunts the use of smart materials and an innovative design, we can duly capture the kinetic energy generated by the joint, have it converted into electricity and power electronics simply by walking, any time any place.

‘The human body is a rich source of energy, especially kinetic energy, which can be harvested for the generation of electricity,’ remarked Dr. Gao Fei, postdoctoral fellow in the Department of Mechanical and Automation Engineering who is the main inventor. ‘The human knee joint has a larger range of motion than other lower limb joints such as ankle and hip. Moreover, the knee’s motion primarily occurs in a sagittal plane, which makes the capture of kinetic energy by the harvester much easier.’

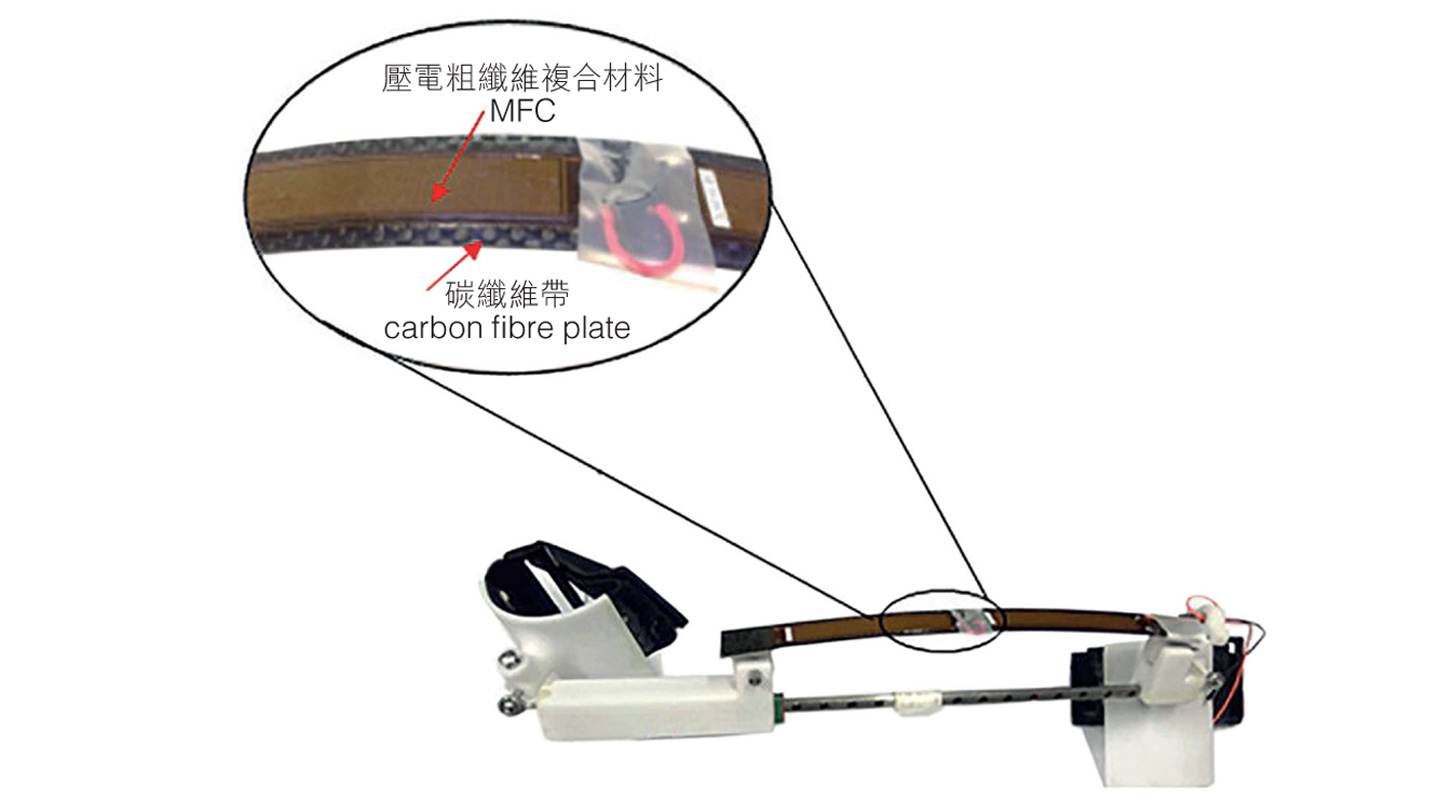

To capture the knee’s energy and convert it into electricity, the human motion researchers fashion their human knee energy harvester after the slider-crank mechanism (figure 1). To begin with, we have two fixing bands at the thigh and shank which fasten the device to our limb. From the thigh and shank fixing bands extend the thigh and shank links, respectively, which meet at a movable bearing at the knee. A linear guide, moreover, connects the thigh and shank links at their ends at the corresponding fixing bands, and a slider glides along it.

‘When walking, our leg flexes and extends, causing the slider to move back and forth. The rotary motion of the knee is thus transformed to linear motion along the slider,’ explained Professor Liao.

And this is not the end of the story: a carbon fibre plate with smart materials on it arches over the design, with one end of it hinged on the thigh fixing band and another on the moving slider. The slider’s movement arising from our gait would cause the carbon fibre plate to bend and the smart materials on it would deform, converting the pressure it receives into electricity.

Such smart materials are macro-fibre composite (MFC) slices that are piezoelectric in nature, with piezoelectric referring to its ability to convert mechanical energy into electrical energy or vice versa. Here, it means the materials can generate electricity once they come across any mechanical effects, in this case pressure and deformation. Placed side by side on the bending beam, the two MFC slices are available on the market and cost $700 each. ‘In mass production, the cost can be lowered,’ Professor Liao said.

At a normal walking speed of 4 km per hour, the MFC human knee energy harvester generates 1.6 milliwatts of power, i.e., 1.6 millijoules per second. This would be sufficient to power small devices such as health monitoring equipment and GPS devices. The Huawei smart band, to give you an idea, consumes one milliwatt on average. The harvester would therefore be able to power it.

‘The power generated by the harvester can either be stored, or put through to other portable and wearable appliances as in the Internet of Things. It offers a good solution to the battery problem, as it allows us to utilize energy locally. In mountaineering, for example, where charging may be a problem, we do not have to rely on batteries, as we can get energy direct from our own motion. It would be good for safety and emergency purposes,’ said the professor.

What’s more, this modern-day talaria is a lightweight one, weighing only 307g. ‘It should be the lightest among the current energy harvesters, and the first one to combine the strengths of smart materials and a mechanical structure,’ said Dr. Gao. Professor Liao added, ‘The design is important—it is the MFC slices combined with the innovative design, a mechanical structure which makes it work.’

And there’s still one crowning feature: the invention produces energy at no cost to us. The research team had performed experiments of walking with and without the harvester, and found out it does not increase the users’ metabolic effort. Using ball joints at the bearings of the thigh and shank fixing bands, the harvester caters to all knee movements, issuing even more energy in intense activities like running and in soccer games. And as demonstrated by Dr. Gao on the spot, it is easy and comfortable to wear.

Taking five months to develop, the energy harvester we now see is the third generation, and the team is looking to improve its energy efficiency through altering its mechanical structure or the palette of composites in the slices. They also seek to enhance the design, increase its comfort and lower the cost. Indeed, after its publication as a featured article in Applied Physics Letters, a top journal in applied physics and in energy harvesting in July 2019, the team has been greeted with wide media and commercial interests, and enquiries are flying in for possibilities to commercialize the device, say, to integrate the design into clothing. With this in view, they are now filing patents in the US and China. And in two years’ time, we will see the prototype developed into a full-fledged product in the market, soothing our nerves and affording us the boon of streaming energy at no extra effort.

Amy L.

This article was originally published in No. 549/550, Newsletter in Jan 2020.