Forging a new frontier for highly adaptable smart metamaterials

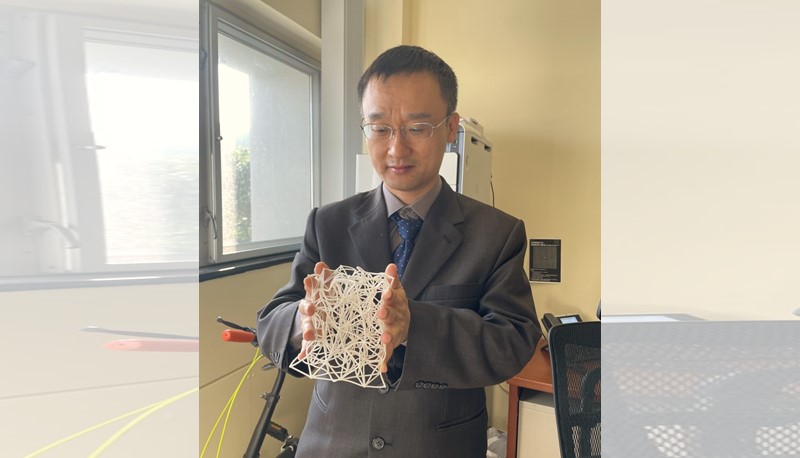

A 3D-printed model demonstrates smart metamaterials with widely adjustable elasticity.

Scientists have long sought to create materials whose elastic properties can be flexible when required, but rigid and difficult to compress when resistance to stress is needed. Such an advance in material technology would have vast potential for application in building materials, anti-vibration materials and impact protection materials, among other uses.

Now, a team of physicists from CUHK has made a theoretical discovery that brings us closer to ‘smart metamaterials’ whose hardness, softness, compression and expansion can be freely adjusted in response to changes in the external environment. Led by Prof. Lei Xu of CUHK’s Department of Physics, the team has created proof-of-concept prototypes in the laboratory and is now seeking partners to develop real-life applications.

Discovering the close connection between topology and elasticity

Prof. Xu’s research focus concerns soft condensed matter physics, which studies everyday phenomena such as drop splashing, water freezing and particle packing. Building on this work, the team’s latest study discovered the close theoretical connection between a material’s elasticity and its topology for the first time.

Aided by 3D printing, Prof. Xu’s team designed a unique topological network structure which comprises nodes that correspond to the core of a particle and are linked by bonds. The particles are packed together so tightly that the nodes eventually reach a point where they jam. At this point, the system becomes rigid and changes from a liquid-like to a solid-like state. As the packing density is increased even further, the topology of the network changes at another transition point which enables a powerful tuning of the elasticity.

The team discovered that the elasticity of the material can be freely altered near this specific ‘topology transition point’ by adding or reducing network connections. They successfully produced a new type of smart elastic metamaterial whose soft, hard, expanding and shrinking properties can be freely and independently adjusted.

Hard to soft, and back again: A wealth of possible use

Prof. Lei Xu is working towards turning the smart materials into real-life applications.

‘Being broadly tuneable according to requirements is a smart material’s crucial property’, says Prof. Xu. ‘A smart material is one that is flexible to changes in an external environment. Once you have a framework, you have the freedom to systematically change the properties in this one single framework and that ability is important for smart systems and smart materials.’

At this stage, the team has created a theoretical framework that has been experimentally realised in the laboratory through a fabricated smart spring system and 3D-printed metamaterials with adjustable elastic properties. The next attempt is to make real materials based on this structure.

For example, one potential application could be protective materials around packages, or protective gears to be worn in hazardous and industrial situations. Prof. Xu’s team is eager to speak to various industries to understand their needs and develop a range of prototype ideas that will bring cutting-edge smart material applications closer to reality.

The research was supported by funds received from the Research Grants Council of Hong Kong, the National Natural Science Foundation of China and the Guangdong Natural Science Fund. The findings have been published in the prestigious scientific journal Nature Materials.

Read more: