Beating microplastics with a revolutionary sustainable sunscreen

Chemists from CUHK have come up with an innovative technology to develop an environmental-friendly sunscreen.

Chemists from CUHK have developed an innovative advanced materials technology that can power the next generation of sunscreen products, providing much-needed protection from the sun while also being kind to people and the planet. The technology can fabricate tiny, hollow inorganic ‘microspheres’ that remove the need for harmful chemicals and microplastics in sunscreen.

From premature ageing to skin cancer, the sun’s UV rays can damage human skin in all sorts of ways. It is vital to apply sunscreen and sun protection products, particularly in hot and tropical climates. However, active ingredients used in these products can create problems of their own.

Most damaging are products that use chemical UV filters, such as oxybenzone, to absorb UV rays. These filters are harmful to coral reefs and are banned in several countries. They can penetrate skin which cause allergic reactions and hormone disruption. Less harmful are products that use physical UV filters like titanium dioxide and zinc oxide, which reflect UV rays. However, these cost more to produce and they are with poor texture, sometimes leaving white marks. Worse still, some manufacturers use microplastics to fix this problem, bringing harmful effects to the environment.

A safe, green and economical alternative

Prof. To Ngai, Assistant Dean (Research) of the Faculty of Science, Professor in the Department of Chemistry and founder of O-Spheres Limited, has discovered an ingenious alternative based on novel hollow microsphere technology. This fabricates tiny hollow particles with precisely controlled physical properties such as shell thickness, permeability, mechanical strength and biocompatibility.

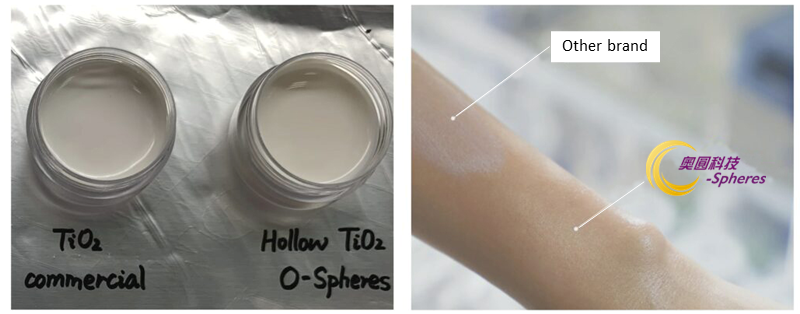

Using microspheres, Prof. Ngai’s team created the O-Spheres Sunblocker, a physical blocker which ‘packs’ titanium dioxide with a hollow structure. This boosts its UV scattering properties, reflecting 95-98% of UV light, while making it cheaper and enhancing the sunscreen texture.

‘We will be able to develop products, which is safe to human, with the same level of UV protection but without large amounts of titanium dioxide,’ said Prof. Ngai. ‘That will reduce the cost of physical UV filter-based sunscreen and it is easy to incorporate the novel filters into existing sunscreen formulation. It also solves the problem of unwanted marks on the skin, particularly for people with dark skin.’

Without large amounts of titanium dioxide, the new sunblock solves the problem of unwanted marks on the skin in comparison with a commercial physical sunscreen.

Hollow spheres for a greener globe

O-Spheres is a start-up founded by Prof. Ngai to commercialise this technology by licensing the product to skin care product manufacturers and brands. It is working with a local partner to scale up production to commercially viable levels over the next two years.

Hollow microsphere technology is also already being applied to industrial printing, which typically uses titanium dioxide to make white ink. The high density of titanium dioxide means that the nozzles of printing machines frequently get blocked due to sedimentation. Prof. Ngai developed a white ink with a hollow structure that reduces density and prevents clogging.

Hollow particles can be used in engineering plastics to reduce weight of materials such as those used in car bumpers and interiors, making vehicles lighter and cutting carbon emissions.

‘O-Spheres’ mission is to engineer hollow microspheres to build a greener globe,’ said Prof. Ngai. ‘We are looking forward to exploring new applications of our technology to promote carbon neutrality and build a better future.’

Read more: